ARTICLE DIRECTORIES

1. What are the names of CPP film, OPP film, BOPP film, and MOPP film?

2. Why does the film need to be stretched?

3. What is the difference between PP film and OPP film?

4. How is the difference between OPP film and CPP film?

5. What are the differences between OPP film, BOPP film, and MOPP film?

1. What are the names of CPP film, OPP film, BOPP film, and MOPP film?

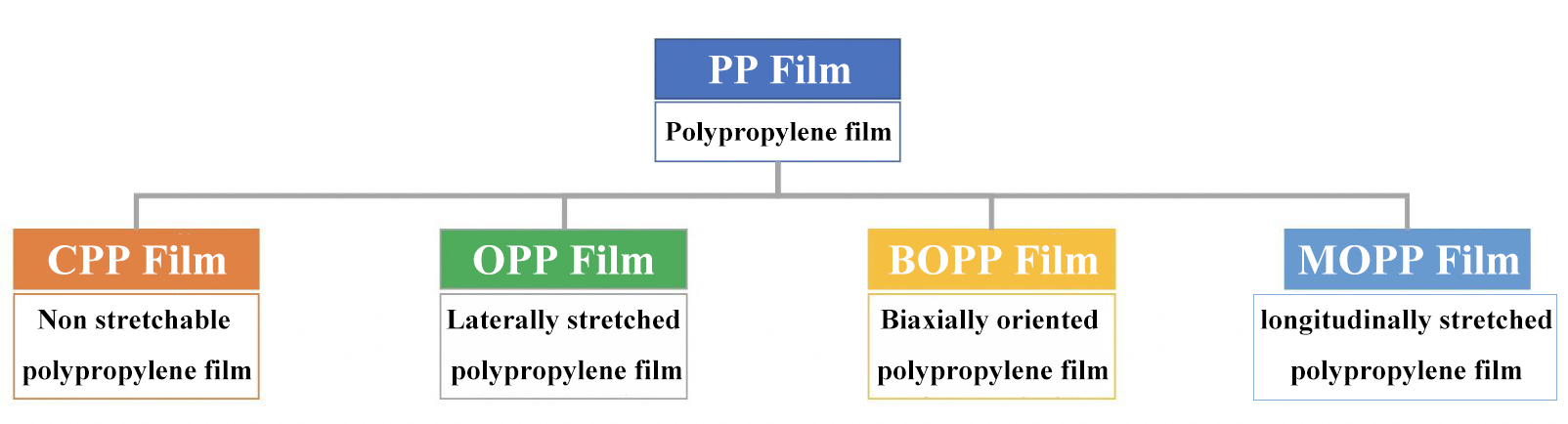

PP film refers to the general term for "polypropylene film", By using different production methods, PP films with different characteristics are produced,And applied in different fields, and extended to other names, The main common names are: CPP film, OPP film, BOPP film, MOPP film, These four names are all made of PP film, which is produced using PP plastic raw materials through extrusion machines, Different names have evolved through different "film stretching" processes.

The following marked in red indicate differences in the "film stretching method"

1. C PP film: abbreviation for C ast Polypropylene,

The term "cast polypropylene film" refers to a non stretchable, non oriented flat extruded film.

2. O PP film: Abbreviation for Oriented Polypropylene,

Namely, 'unidirectional stretching of polypropylene film', in the TD direction of unidirectional stretching.

3. BO PP film: abbreviation for Biaxially Oriented Polypropylene,

Namely "biaxially stretched polypropylene film", stretching in the MD and TD directions.

4. MO PP film: abbreviation for Monoaxially Oriented Polypropylene,

Namely, 'unidirectional stretched polypropylene film', unidirectional stretched in the MD direction.

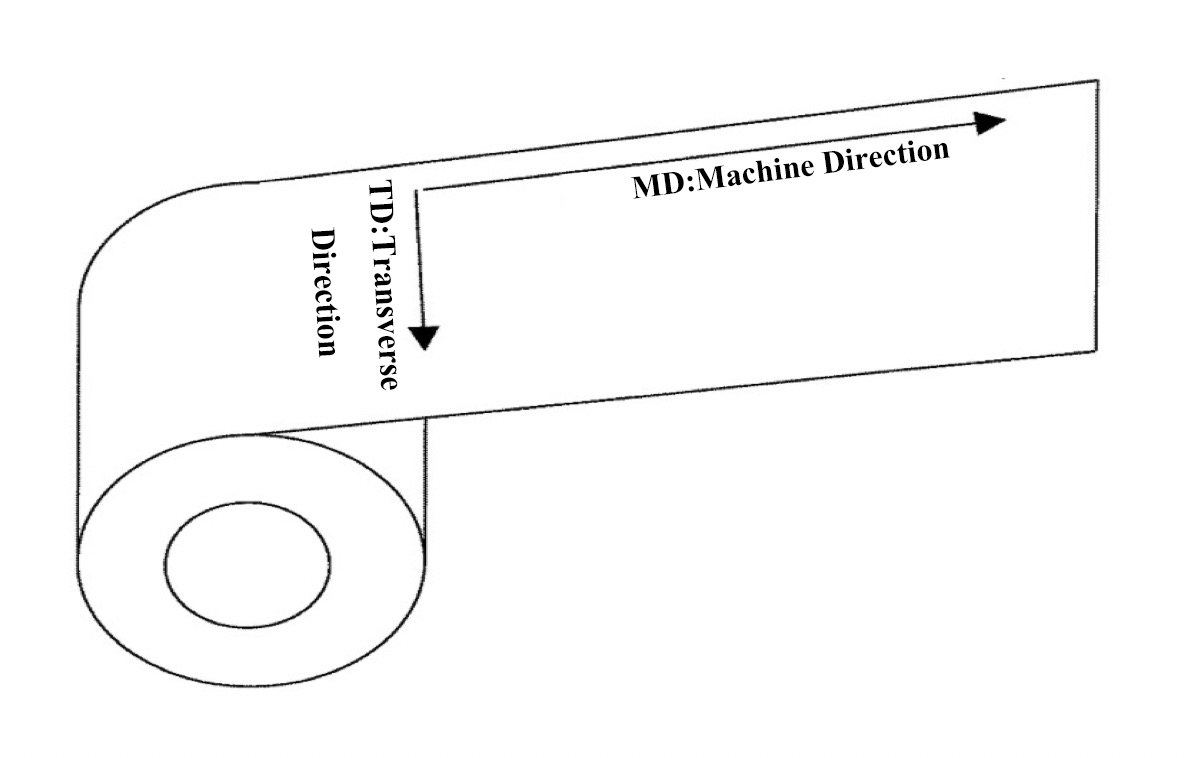

▶MD direction: Refers to the Machine Direction, which is the longitudinal direction of the film.

▶TD direction: Refers to the Transverse Direction of the film.

2.Why does the film need to be stretched?

Usually, the reason why plastic film needs to be "stretched" is for the following purposes:

1. Improve dimensional stability.

2. Improve mechanical properties.

3. Improve glossiness and transparency.

4. Improve air resistance.

The above four points are the reasons why the film needs to be stretched,Due to the stretching of the polymer, it can arrange the stretching direction of the polymer in a regular manner, generate a high degree of coordination, improve material density and film strength,increase gas resistance, improve mechanical properties, and increase surface glossiness and transparency.

3.What is the difference between PP film and OPP film?

PP film refers to polypropylene film, and the commonly referred to PP film may be CPP film, BOPP film, or functional PP film (PP protective film, PP luminous film, PP composite material film), so PP film is only a broad term.

In fact, there may be PP films with different functionalities or stretching processes.

OPP film is a thin film product that uses a "unidirectional stretching method" on PP film, allowing the film to extend in the TD direction, resulting in better tensile strength, glossiness, gas resistance, etc It is very suitable as a product packaging bag or transparent tape.

<Conclusion>

The raw materials for PP film and OPP film are both polypropylene,

PP film is just a general term for polypropylene film,

After stretching the PP film through the TDO extension machine, an OPP film is produced,

And OPP film enhances mechanical properties, making it suitable for use as packaging bags and adhesive tapes.

4.How is the difference between OPP film and CPP film?

CPP film is also known as cast polypropylene, also known as unstretched polypropylene film.

The plastic is melted into the raw material through an extruder, extruded through a T-shaped structure molding mold, flowing in a sheet shape onto a cold casting roller for rapid cooling, and then pulled, trimmed, and rolled to complete the product.

Due to this process, CPP membranes have several characteristics:

-Higher stiffness than PE film.

-Excellent barrier for moisture and odor.

-Customized blending to produce more functional membranes.

-No solvents are used during the production process, which is relatively environmentally friendly.

-With lightweight, high strength, high toughness, and excellent impact resistance, it is the preferred choice for composite materials.

<Conclusion>

The biggest difference between CPP film and OPP film is whether the film is stretched or not. OPP uses stretching technology to enhance the performance of the film. Although CPP film is not stretched, the formula can be adjusted according to customer needs, making its application more widespread and changing more.

For example, changing the color, fog surface, bright surface, anti fog, printing, etc. of the film Various functional PP films can be produced through different formulas.

5.What are the differences between OPP film, BOPP film, and MOPP film?

BOPP film is a biaxially stretched polypropylene film

OPP film is a Laterally stretched polypropylene film

MOPP film is a longitudinally stretched polypropylene film

We will discuss with the most commonly asked questions of "OPP film vs. BOPP film" and "OPP film vs. MOPP film":

a. What is the difference between OPP film and BOPP film?

The physical properties and characteristics of OPP and BOPP membranes are not significantly different under actual usage conditions, and they are even treated as the same membrane. As OPP is produced by a extruder, the membrane is already stretched longitudinally (MD direction) during the production process, and then horizontally (TD direction) by an extension machine. The entire process is in the form of "biaxial stretching", so the results are similar to those of BOPP membrane biaxial stretching using a biaxial extension machine, Therefore, there is no significant difference in characteristics between OPP film and BOPP film.

The methods of unidirectional stretching and biaxial stretching, if applied to PET or PC materials, will produce different characteristics,

There is a significant difference in optical performance or refractive index between PET and BOPET. But when used on PP film, the difference is relatively small.

b. What is the difference between OPP film and MOPP film?

OPP film extends "Laterally of the film", while MOPP film extends "longitudinally of the fim". When MOPP film extends longitudinally, it stretches "clockwise" of the molecular chain, so the longitudinal tensile strength is strong, but the transverse tensile strength is weak, making it easy to fracture.

OPP film, due to its similar properties to BOPP film mentioned above, is not prone to fracture in both longitudinal and transverse directions and has basic tensile strength.

<Conclusion>

a. What is the difference between OPP film and BOPP film?

From the perspective of production techniques, the two are products produced by different techniques.

From the perspective of application, the two are considered the same product because the differences in characteristics are very small.

b. What is the difference between OPP film and MOPP film?

Longitudinal tensile strength of membrane: MOPP membrane>OPP membrane

Therefore, MOPP film is suitable for applications with unidirectional properties and high tensile strength.

The OPP film has a certain basic tensile strength in both the longitudinal and transverse directions.

The above is a compilation and sharing of online literature,If you have procurement requirements for CPP film, OPP film, BOPP film, MOPP film, please contact us:

Post time: Jul-26-2023