Basic information

Chinese name:金葱粉

Other names: flashing powder,

Gold and silver flakes, flash flakes

Materials:

PET, PVC, OPP, aluminum

Application

Handicrafts, cosmetics, garment accessories,sealant,etc..

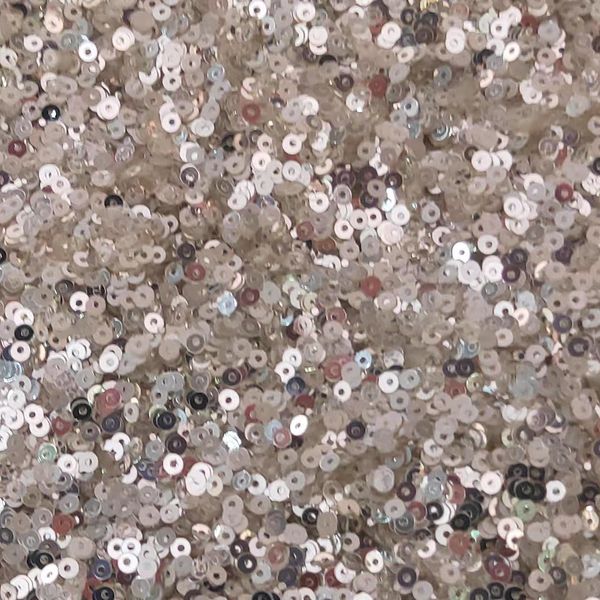

Glitter powder is also called glitter or flashing powder,those with bigger sizes are also called sequins. It is made of PET, PVC, OPP,sometimes with the metal aluminum. These film materials with high brightness and different thicknesses,after plating and coating, is finished with precision cut. The particle size can be produced from 0.004mm-3.0mm. The environmentally friendly one is made of PET. Its shapes are quadrangular, hexagonal, rectangular,and prismatic, etc.. As a surface treatment material with unique effects, glitter powder is widely used in Christmas crafts, candle crafts,garment accessaries,cosmetics,screen printing industry (cloth, leather, footwear, shoe materials, Chinese New Year pictures series,etc.), decorative materials ( glass art crafts, polycrystalline glass; crystal picture glass, crystal ball,etc..), paint decoration, furniture spray painting, packaging materials, Christmas gifts, toy pens and other fields,etc..Its feature is to enhance the visual effects of the product, making the parts of the surface has layers feeling of concave and convex and a more three-dimensional effect.

Product introduction

Glitter powder is made of materials such as PET, PVC, OPP, metal film of aluminum,etc.which are highly bright and with different thicknesses, and made by plating and coating before precise cutting. Glitter’s colors range from laser silver, laser gold, laser colors (including red, blue, green, purple, pink, black,etc.), silver, golden, and other colors (red, blue, green, purple, pink, black),also illusion series. Each color system is added with a surface protective layer, the color is brightful, and it has certain resistance and temperature resistance to mildly corrosive chemicals in certain climate and temperatures.And its high flashing characteristics make the decorations sparkling and dazzling.

It is also widely used in some cosmetics, such as eye shadow, as well as nail polish and various nail products.Glitter powder has a luminous effect formed by adding the upper layer of plastic/aluminium films, which is widely used in the food packaging industry, but it is strictly forbidden to add glitter powder into food.

With the continuous development of science and technology, the application of glitter powder in various fields will become more and more extensive.

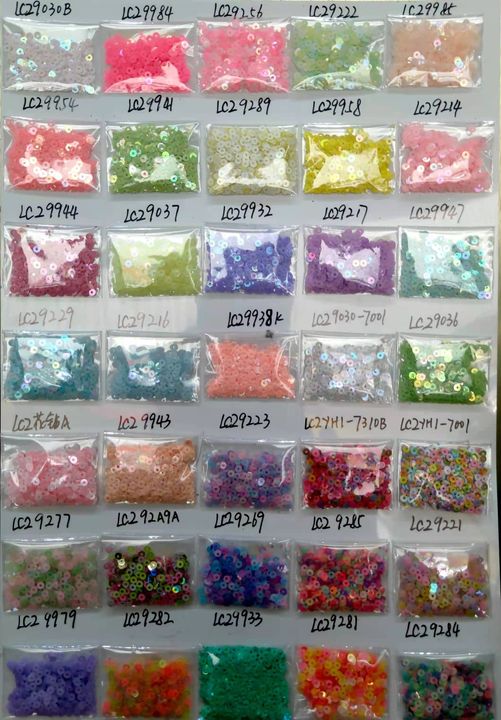

Product Categories

This product is composed of vacuum metal polyester plastic-films, and its color layer is a thermosetting crossbonded epoxy layer. It can produce a wide range of colors and can be used for wood, paper, cloth, and metal by screen printing, coating, and spraying,and used on wood,paper,cloth,metal,leather goods, ceramics and other materials,forming special and eye-catching effects as decoration or reflection. Glitter powder made of PVC is not resistant to high temperature (60°C), acid and alkali. Glitter powder made of PET material is resistant to high temperature (190°C), with acid and alkali resistance.

1. Metallic Glitter

The product consists of an extremely thin aluminum foil with a colored outer layer of thermoset cross-bonded epoxy. Glitter is suitable for many soluble materials and can also be applied dry. Metallic glitter is an ideal material for plastic products, with a temperature resistance of 250°C and is also resistant to acid and alkali.

2. Symphony Series

This product is an unique illusion feeling glitter, which does not contain metal components, but due to the optical properties of the polymer film that makes up the product, the product has metallic color changes and luster, and has obvious color changes. It is especially suitable for industries such as printing, crafts, cosmetics, jewelry, etc.so that the products have a color-changing appearance.

3. Laser Series

The product is made of imported highly-brightful and highly-colorful original laser film, which is coated and colored at high temperature, and cut by professional precise machinery to form sequins with uniform specifications and shapes. The original film is generally an environmentally friendly PET laser film, and the price of the laser glitter produced is relatively high. Because the reflective effect of the laser glitter powder is better than that of the general glitter powder, and is generally used in injection molding, glass building materials and other industries to show its shiny surface.

Product Specifications

Quadrangular

0.1mm、0.3mm、0.4mm、0.5mm、0.6mm、0.8mm、1.0mm、3.0mm

Hexagonal

1/500(0.05mm)、1/360(0.07mm)、1/256(0.1mm)、1/170(0.15mm)、1/128(0.2mm)、1/96(0.3mm)、1/64(0.4mm)1/40(0.5mm)、1/32(0.6mm)、1/24(0.8mm)、1/20(1.3mm)、1/12(2.0mm)、1/10(2.5mm)、1/8(3.0mm)1/6(5mm)0.1751/4(6.0mm)0.20

Strips

0.3x1.5mm、0.3x3mm、0.3x4.7mm、0.2x1.5mm\0.2X1mm\0.1X0.8mm

There are many types, colors and specifications of glitter powder on the market.High-quality glitter powderusually is reflected in the following indicators:

1. High brightness: Judging from the brightness of thesurface layer,high-quality glitter powder is high flashing, highly bright, and with a obvious mirror effect.

2. Unified shape: high-quality glitter powder, e.g.the shape of the glitter powder can be seen under a microscope and it is Standard hexagonal shape, without uneven sizes or with powder.

3.Resistant to strong acid and alkali:high-quality glitter,soaked in strong acid and alkali liquid for a long time, it still keeps the color bright.

4. High temperature resistance: It can be steamed and cooked. After the glitter powder is steamed at high temperature, it is the top grade of quality without fading or partial fading.This method is mostly used to identify powdered glitter used with glue and nail polish.

Production Process

The whole production process of ordinary glitter powder is divided into five parts, which are vacuum plating, high temperature coating printing, material stripping, powder cutting,powder screening and removal processes,etc.,and finally there are weighing,packaging and shipping. The core process that determines product quality is the production link of high temperature coating printing. This process will deter- mine the brightness, high temperature resistance and solvent resistance of scallion powder.

Hongze Import and Export Co.Ltd. focuses on the production and marketing of flexible packaging items e.g. packaging materials and bags, but also can pro-vide high quality and cheap glitter powder, sequins and sequin decorative film/sheets, welcome to contac us, we look forward to our happy cooperation!

#decorative #vinyl #craftvinyl #film #craft #diy #rainbow #manufacturing #paper #paperindustry #converting #sign #signage #vinyl #decorativefilms #holographic #holographicfilms #packaging #crafts #tape #label #adhesives #crafting #art #rainbow #sequins #glitter#manufacturing #paper #film #signsolutions #signshop #graphics #projects

Post time: Dec-22-2022