For high-quality printed materials, the color often has a relatively fixed measurement standard: the ink color of a batch of products should be consistent in front and back, bright in color, and consistent with the ink hue and ink color of the sample sheet.

However, in the process of printing and storage, the hue, lightness and saturation of printed matter often change. Whether it is monochrome ink or ink with more than two colors, the color may become darker or lighter under the internal and external effects.

In view of this situation, we will discuss with you today the factors that affect the color change of printed materials, which generally involve the following aspects:

Discoloration and fading of ink due to light intolerance

Under the sunlight, the color and brightness of the ink will change in varying degrees. There is no ink that is absolutely light resistant without changing the color. Under the strong sunlight, the color of all inks will change in varying degrees. This change can be divided into two types.

Fading:

Under the action of solar ultraviolet light, the ink has poor light resistance, lost its original bright color, and the color becomes pale to gray white. In particular, yellow and red colors fade faster in light color inks and four color overprinting, while cyan and ink fade more slowly.

Discoloration:

Contrary to the fading of the black ink of printed matter, the color changes deeply under the effect of sunlight, and the color also changes. People call this change discoloration.

Effect of emulsification

The offset printing plate cannot be separated from wetting the blank part of the plate with a wetting solution. For offset printing, water is applied first and then ink is applied. Emulsification is inevitable when water is used.

The color of the ink will be reduced after emulsification, but it will recover its original color after the water evaporates. Therefore, the larger the water is, the greater the emulsification amount will cause discoloration. In particular, the color inks with completely different emulsions are mixed together, and the phenomenon of discoloration is particularly prominent.

Nature of paper

1.Surface smoothness of paper

The smoothness of the paper surface is closely related to the printing copy. The uneven paper surface often needs greater pressure to make the ink have good contact with it. For example, if the ink viscosity, fluidity and ink layer thickness are kept at a certain amount, increasing the pressure will often increase the spread area of the print. At the same time, the low concave parts of the paper are still in poor contact. For example, if the printing effects of coated paper and newsprint on the same printing plate are quite different, the different replication effects can be clearly compared.

2.Absorption of paper

The absorbability of paper is also directly related to the replication effect. Generally, when printing loose paper, if the ink has high fluidity and low viscosity, the paper will absorb more ink layer connectors. If the diameter of the pores is larger than the diameter of the pigment particles, even the pigment will be absorbed, which will reduce the saturation of the impression. The ink layer thickness needs to be properly increased.

However, increasing the thickness of the ink layer will cause "spreading" at the moment of imprinting, which will affect the impression copy effect. The paper with low absorption can make most of the ink film appear on the paper surface, so that the printed ink layer has better saturation.

3.Permeability of paper

The high permeability of paper will reduce the thickness of ink layer, and the large pores on the paper surface will also make some pigment particles permeate into the paper at the same time, so the color will have a sense of fading. For this reason, use paper with rough surface and loose texture, and paper with large ink fluidity, pay attention to discoloration.

Heat resistance of pigment

In the drying process of ink, bright and fast drying adhesive printing ink is mainly oxidized conjunctiva drying. There is a fixation stage before the drying of offset printing ink. The oxidation polymerization of the ink is an exothermic reaction. If the drying is too fast, a lot of heat will be released. If the heat is emitted slowly, the heat resistant pigment will change color.

For example, the golden ink darkens and loses its original luster.

When printing, the sheets are stacked in stacks on the paper receiving table. Due to too much stacking, the sheet ink in the middle is oxidized, polymerized and exothermic, and the heat is not easy to dissipate. If the temperature is too high, the middle part will change color more.

Effect of Dried Oil

Light color inks belong to cold colors, light yellow, emerald green, lake blue and other intermediate color inks, do not use red dry oil, because the red dry oil itself has a deep magenta, which will affect the color of light color inks.

The white dry oil looks white, but it turns light brown after the conjunctiva is oxidized. If the amount of white dry oil is large, the dry print may be yellowish brown, while the color of red dry oil for dark inks such as blue, black and purple will not be greatly affected.

Influence of alkali resistance of printing ink

The pH value of the printed paper is 7, and the neutral paper is the best. Generally, the ink made of inorganic pigments is relatively poor in acid and alkali resistance, while the organic pigments are relatively good in acid and alkali resistance. Especially, the medium blue and dark blue ink will fade when encountering alkali.

In case of alkali, the medium yellow color will turn to red, and the hot stamping anodized aluminum foil and printing gold will turn to ancient yellow when encountering alkaline substances, without luster. The paper is often weak and alkaline, and the binder containing alkaline is encountered in the later stage of printing and binding. If the packaging and decoration printing products are packaging alkaline substances, such as soap, soap, washing powder, etc., the alkali resistance and saponification resistance of the ink should be considered.

Impact of storage environment

There are several reasons why most printed products will inevitably become yellowish when they are stored for a long time.

The fibers in the paper contain more lignin and discolor. For example, newspapers printed on newsprint are most likely to turn yellow and brittle.

Most of the color printing products overprinted by offset four color dot printing are discolored or faded due to the poor light resistance and heat resistance of the pigment under the sun, long days, wind and rain, outdoor high temperature corrosion, etc.

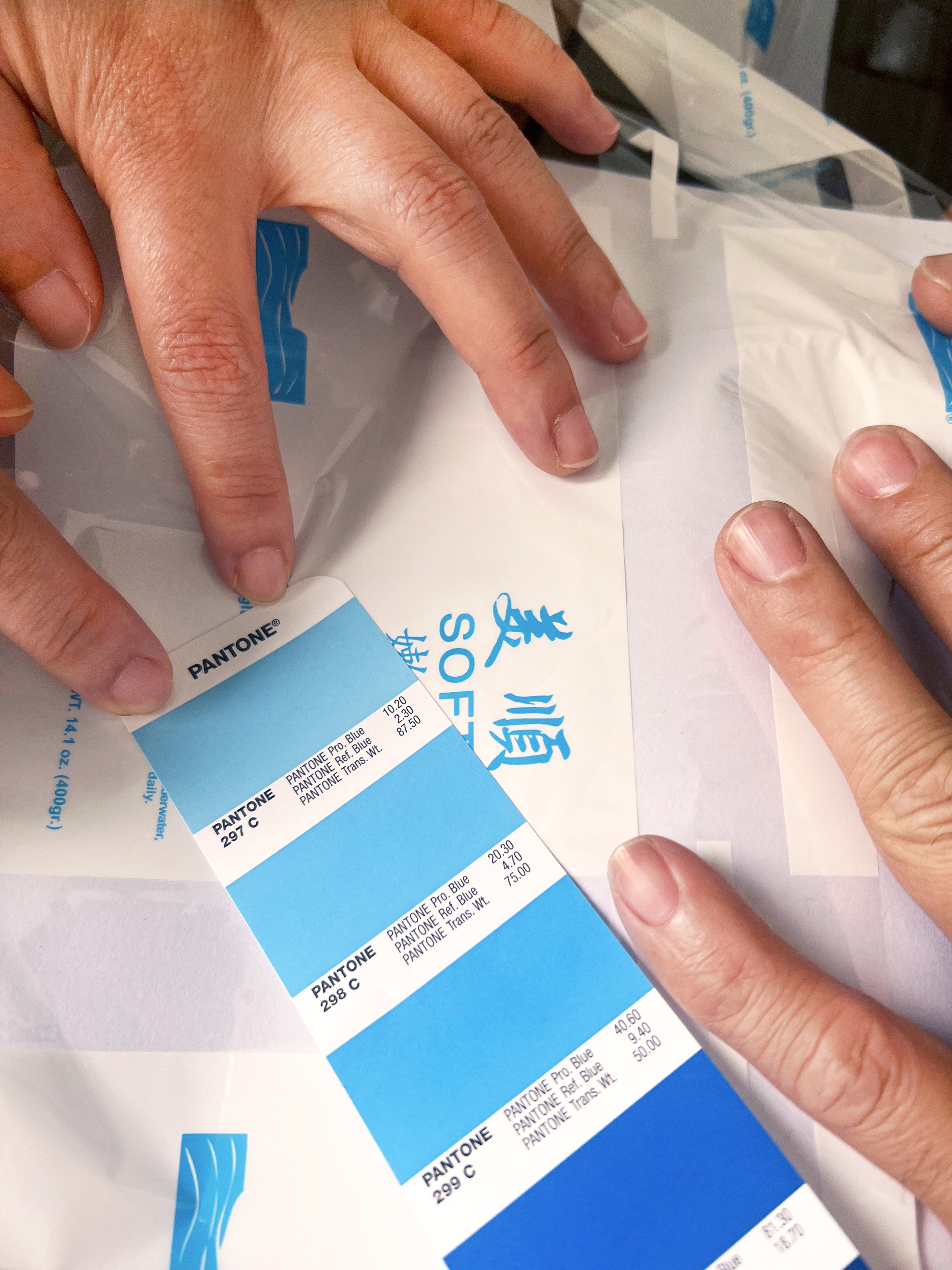

The ink Hongze chooses is not only superior, but also keeps a strict attitude when comparing the color of the finished product in the later stage. Just give us the product, and we will check every step requirements for you.

For more information,please contact us :

Post time: Oct-21-2022