Stamping is an important metal effect surface decoration method. Although gold and silver ink printing has similar metal luster decoration effect with hot stamping, it is still necessary to achieve strong visual impact through the hot stamping process.

The continuous innovation of stamping equipment and supporting materials has enriched the expression forms of stamping techniques. Now there are seven kinds of stamping techniques:

01: Ordinary flat stamping

The most common hot stamping is to leave blank all around to highlight the hot stamping body. Compared with other hot stamping, the production process is relatively simple. If the quantity is not large, zinc plate can be used for hot stamping.Flat stamping means that the datum plane is a flat die, which is stamped on a flat work piece or a part of the work piece.

This kind of impression can be embossed graphics and text, which can be hot stamped on the plane; It can also be a flat silicone plate, which is hot stamped on the raised image and text.

02: Field anti-white stamping

Contrary to the flat stamping method, the subject part is left blank, while the background part is hot stamping. The size of the hot stamping area depends on the product design requirements. If the hot stamping area is large, it is necessary to consider whether its adhesion performance meets the process requirements.

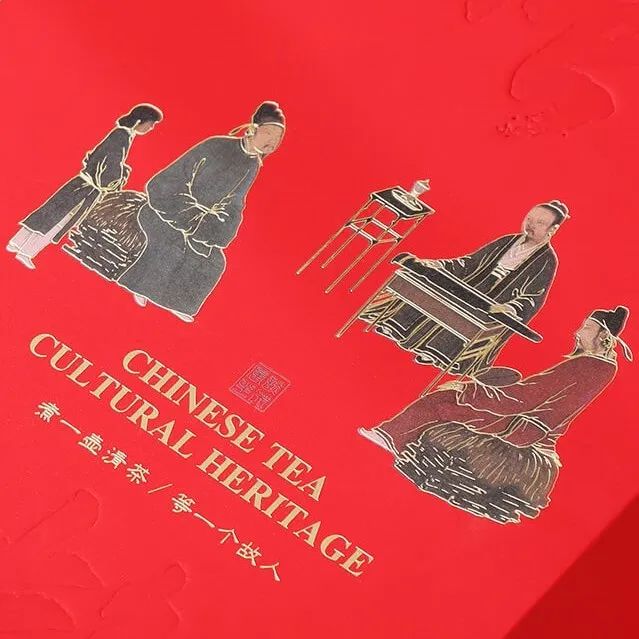

03: Set stamping

According to the needs of the artwork, in order to make the stamping and printing part of the ingenious combination, printing in the stamping first. In the process of production, the alignment is high, and the alignment is accurate to get the perfect effect.

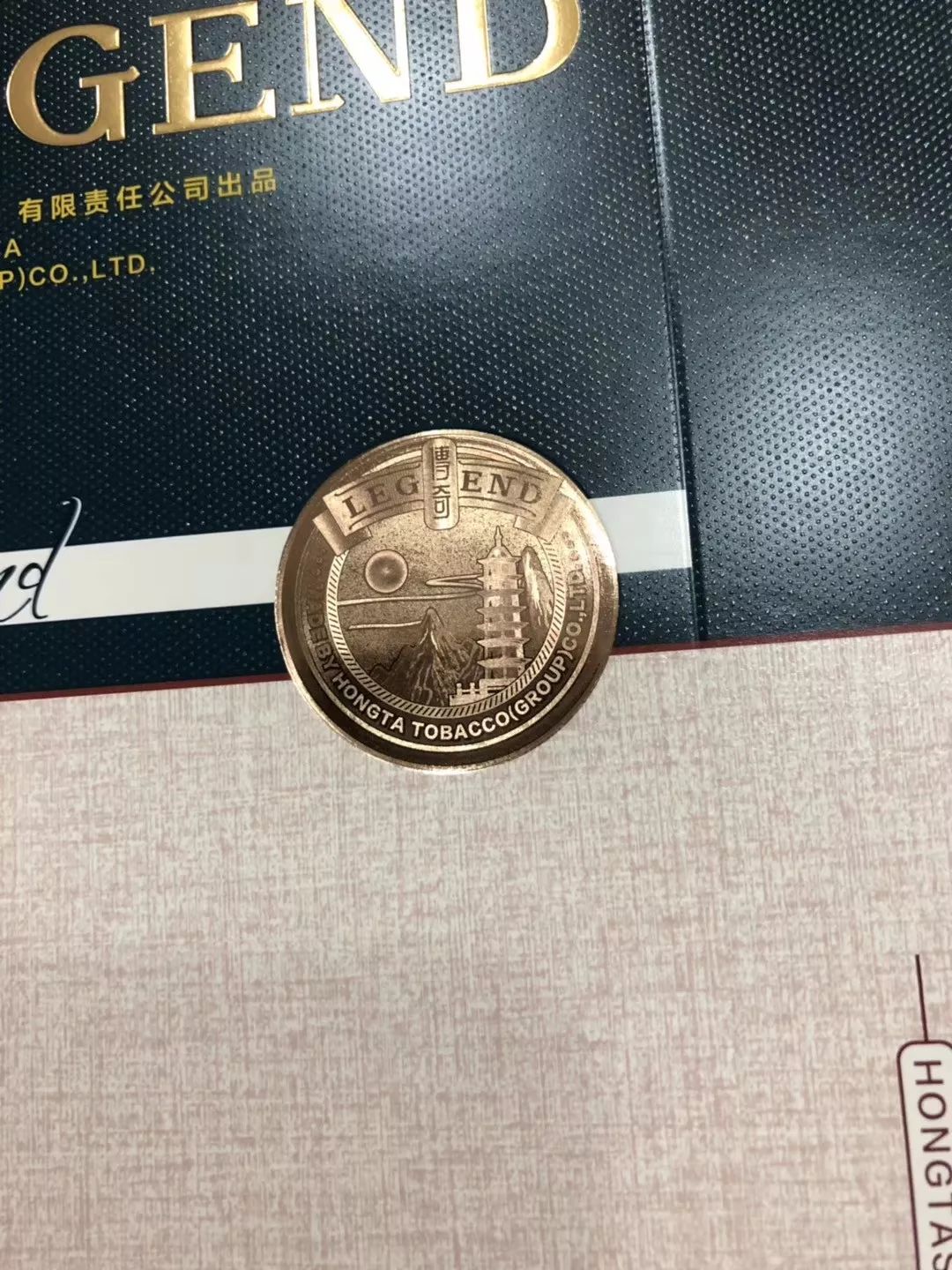

04: Refraction stamping

During the production of the stamping plate, the main image and the background graphics are separated by lines of different thickness or direction to form the refraction effect and emphasize the artistic sense of the graphic lines. Generally, the laser engraving plate is used.

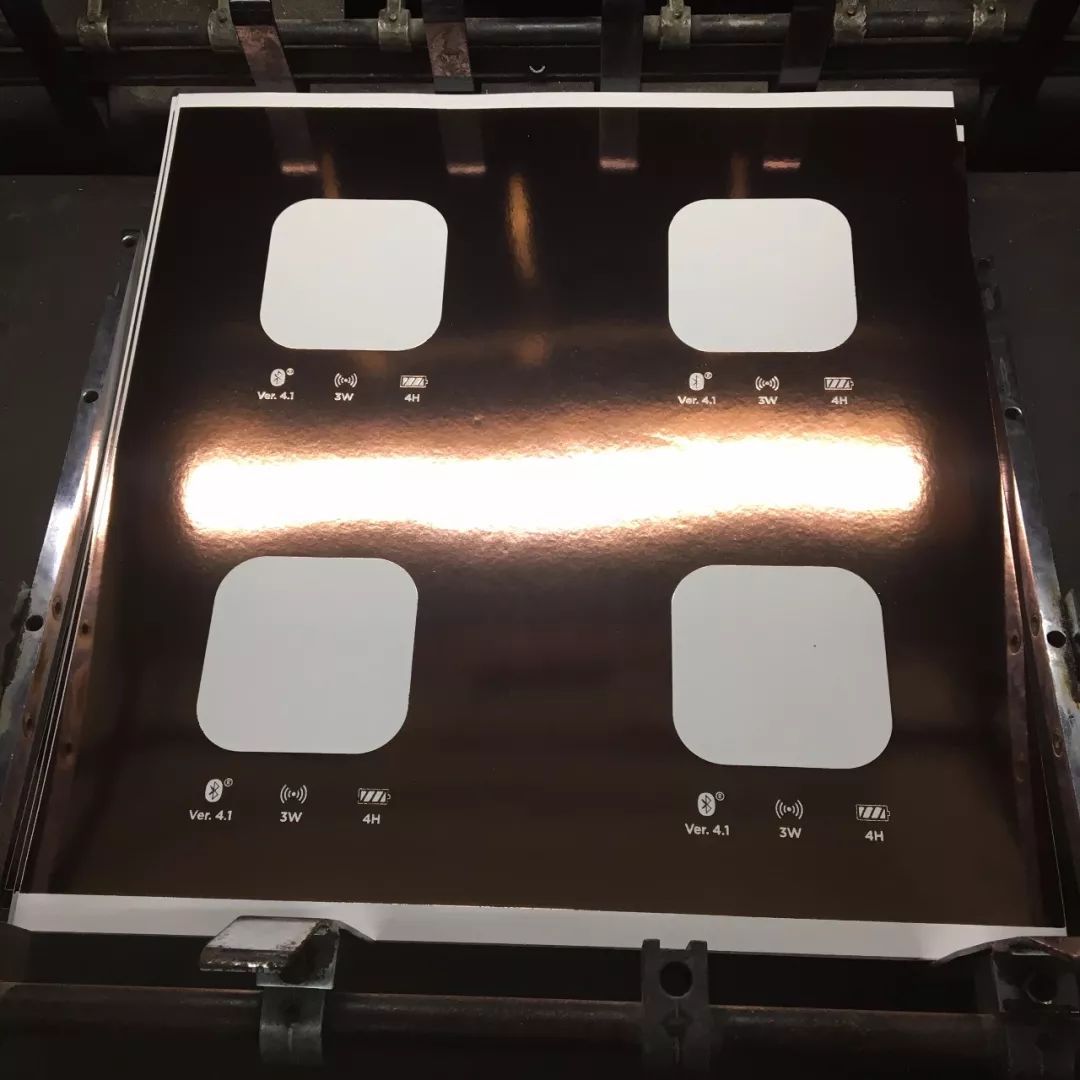

05: Multiple stamping

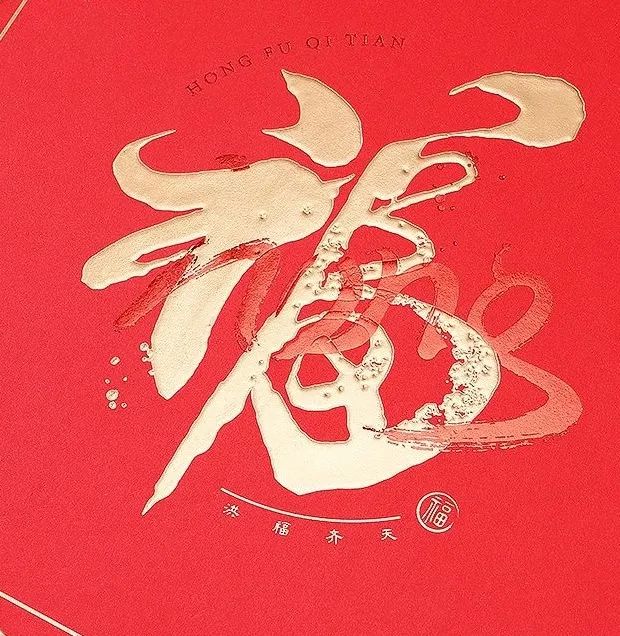

Repeated hot stamping for more than two times in the same graphic area requires multiple process processing. At the same time, attention must be paid to the compatibility of the two gold foils to prevent the phenomenon of loose adhesion.

06: Embossed stamping

It is the same as the embossing and embossing, but embossing and embossing pay more attention to the quality of embossing rather than the embossing effect. Usually, embossing and embossing plates are used, and the embossing height needs to be within the range of the surface tension of the gold foil.

The products processed by embossing stamping technology present embossed three-dimensional pattern effect, so the process of printing before stamping is adopted. At the same time, due to its high accuracy and high quality requirements, it is more suitable to use hot stamping technology.

As you can imagine, designers should carefully consider the texture, weight, gold foil and printing ink when selecting paper or other carrier materials for the three-dimensional stamping process. The alignment of the front and back sides is also crucial.

At the same time, the thickness of the paper will limit the quality and effect of the finished product during the operation. For example, paper that is too thin or has poor toughness will cause paper bursting.

07: Special effect texture stamping

According to the needs of creativity, special effect pattern stamping is made to highlight different special mechanism effects.

In the practical application of hot stamping process, the selection of metal stamping plate, hot stamping paper, paper and stamping expression directly affects the final stamping effect.

Stamping is now widely used in various printing and packaging fields. It is also the only printing technology that can produce bright, non-discolored metal effects on paper, plastic, cardboard and other printing surfaces.

Post time: Feb-07-2023