The popularity of pre made vegetables has also brought new opportunities to the food packaging market.

Common pre packaged vegetables include vacuum packaging, body mounted packaging, modified atmosphere packaging, canned packaging, etc. From the B-end to the C-end, prefabricated dishes have put forward new demands for packaging in the process of facing users directly.

Prefabricated dishes can be roughly divided into three types of food: ready to cook, ready to heat, and ready to eat. Ease and convenience are the pursuit of users who choose instant pre made dishes, as well as the packaging requirements for pre made dishes.

The innovation of packaging by prefabricated vegetable brand enterprises is a decision made after deeply understanding consumer needs and market pain points. Prefabricated vegetable enterprises can only better enhance their core competitiveness by starting from the experience of C-end consumers and continuously researching and innovating, and stand out in the market of prefabricated vegetables in the big waves. The packaging innovation of prefabricated vegetables is showing the following trends.

01 Diversification - Comprehensive packaging renewal

The rapid development of prefabricated vegetables has put forward higher requirements for packaging, and has also driven the diversified development of the prefabricated vegetable packaging industry.

Packaging makes the processing of pre made vegetables more convenient.

Sealed Air Packaging Company has launched Simple Steps technology, which uses vacuum sealing technology to ensure that the fresh flavor and nutritional content of food are maintained in the best state, reducing preparation time, steam heating, automatic exhaust technology, anti scalding handheld position, and easy to open performance, providing convenience for consumers. This packaging can be used directly in a microwave oven without the need to replace the container.

Packaging optimizes the consumer experience.

A company has launched a straight-line easy to open flexible packaging that is easy to tear without damaging the structure of the packaging material. Even after being frozen at -18 ℃ for 24 hours, it still has excellent straight-line tear resistance.

Packaging makes pre made dishes more delicious in quality.

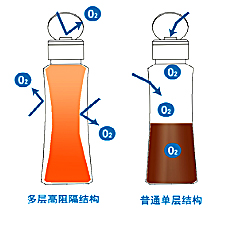

A certain company's high barrier plastic container can better prevent the loss of fragrance from the content and the penetration of external oxygen molecules, enhance its freshness, make food more delicious, and can also be heated in a microwave.

Packaging makes pre packaged cold chain logistics more environmentally friendly.

The new cold chain insulation box developed by Vericool in the United States is mainly made of compostable insulation materials. Discarded insulation boxes can be recycled and can be degraded in 180 days or less.

Sustainable development of prefabricated vegetable packaging materials.

Multiple companies are also working on developing sustainable packaging materials, such as Boraine's fully biodegradable film used for pre packaged clean vegetables (fruits and vegetables). The natural breathability and freshness of biodegradable film can maintain the freshness and shelf life of fruits and vegetables, with advantages such as high barrier and easy opening. It is also easy to recycle and degrade, playing an important role in reducing white pollution and protecting the environment. Its single material PP film, which can be steamed at high temperature, can also be used for packaging ready-to-eat pre made vegetables.

Single material composite films have become one of the important directions for sustainable development in the packaging industry, as single materials are more conducive to recycling and reuse.

02 New opportunities - seeking breakthroughs from multiple perspectives

At present, there are still some defects in the packaging of pre made vegetables, such as air leakage in vacuum packaging, bag breakage during steaming and cooking, and the need to improve the convenience of steaming and cooking, which affect the consumer experience. In addition, prolonged transportation will reduce the freshness of semi-finished vegetables, while a large amount of discarded packaging will lead to white pollution. From the perspective of packaging needs and attention of prefabricated vegetable enterprises, there are three major opportunities for breakthroughs in prefabricated vegetable packaging in the future:

One is the breakthrough in the packaging technology of pre packaged vegetables at room temperature: due to the high cost of cold chain packaging technology, more and more brand enterprises hope to work together with packaging enterprises to develop pre packaged vegetables at room temperature;

The second is the breakthrough in high-temperature cooking packaging technology, improving the performance and application experience of cooking packaging;

The third is the breakthrough in freezing and refrigerated packaging technology, which solves the environmental protection issues of cold chain packaging.

03 New demand - innovative solutions to pain points

Packaging innovation is not only about changes in form and surface, but also a series of precise design points from demand to experience. The packaging innovation of prefabricated vegetables is not only a simple change in packaging form, material, carrier, etc., but also an insight into the audience, scenes, needs, and pain points behind the surface. By utilizing the product form differentiation, functional and experiential satisfaction, and application scenario changes brought about by packaging innovation, it is possible to develop product fission opportunities.

For example, the innovative brand of frozen and fast food cooking bags have gained insights into the pain points of young people in office settings such as lack of time, inability to cook, and unwillingness to wash dishes. Focusing on the microwave food scene, they have innovatively launched unique self-supporting packaging that can be heated by microwaves, achieving innovative solutions to consumer usage scenarios and needs.

According to the 2022 Research Report on the Development Trends of China's Prefabricated Vegetable Industry, the market size of prefabricated vegetables in 2021 has reached 345.9 billion yuan, a year-on-year increase of 19.8%, and is expected to exceed one trillion yuan by 2026. From a long-term perspective, it is expected to achieve a scale of over 3 trillion yuan. If the future pre made vegetable market has a volume of 3 trillion yuan per year, the resulting market demand for packaging bags, boxes, cling films, labels, etc. will exceed 100 billion yuan.

Prefabricated dishes are an inevitable trend in the development of the catering industry, and no one can stop their popularity. For the plastic packaging industry, there is still huge room for the development of packaging materials for prefabricated dishes under the trend of subdivision in the category of prefabricated dishes. Correspondingly, the industrial chain of prefabricated vegetable plastic packaging will also usher in new development opportunities.

Post time: Apr-22-2023